Table of Contents

What is a Crank?

Definition of a Crank

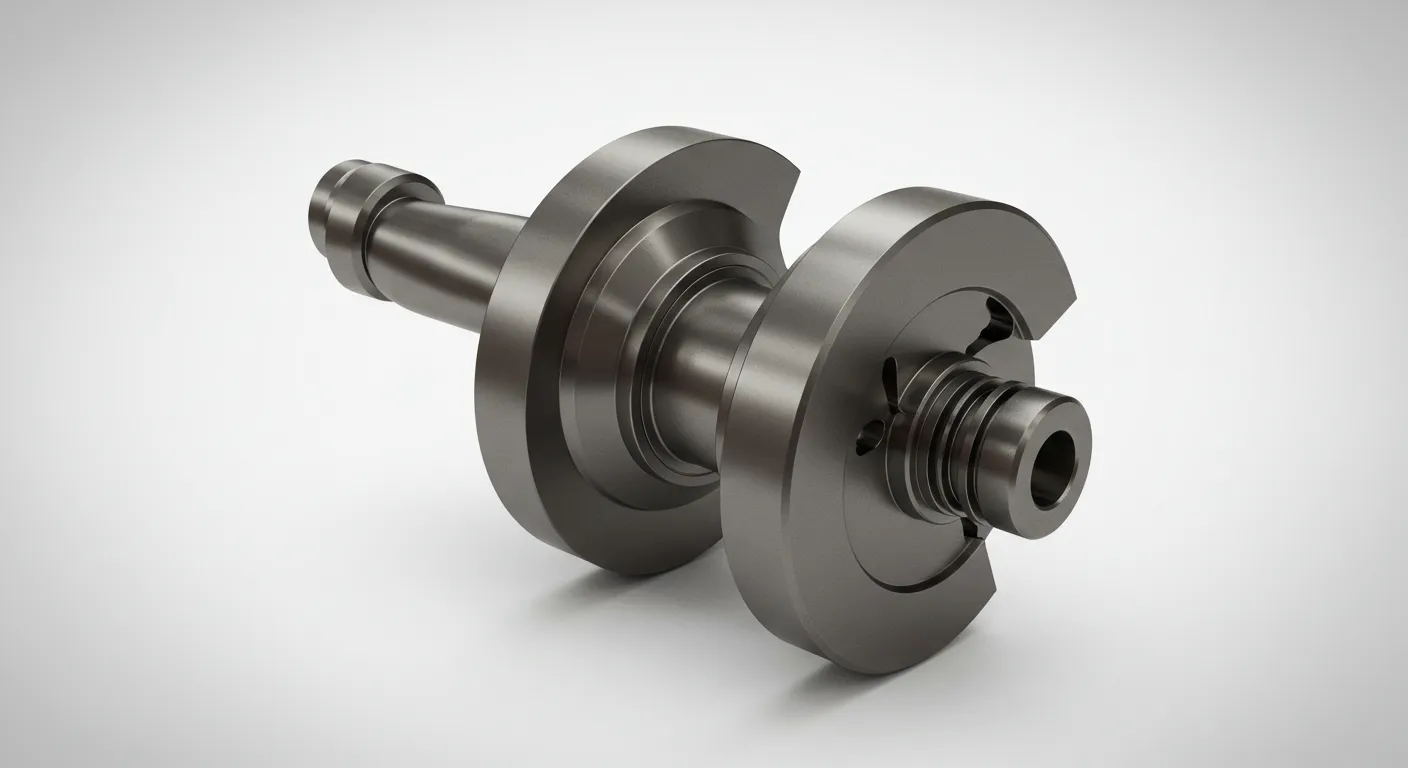

A crank is a fundamental mechanical component used to convert rotary motion into linear motion or vice versa. It typically consists of an arm attached at a right angle to a rotating shaft, enabling efficient transfer of mechanical energy. This simple device is key in many machines and tools. It works in everything from hand-operated gadgets to complex engine systems.

Purpose of a Crank in Mechanical Systems

A crank primarily converts motion. It acts as a bridge, transferring energy between mechanical parts. This function ensures systems operate precisely and efficiently. Examples include engines, bicycles, and industrial equipment. In these, accuracy and energy optimization are crucial.

History of the Crank

Origin of the Crank Mechanism

The crank mechanism has a rich history, with origins dating back to ancient civilizations. Early hand cranks were employed for basic tasks like drawing water from wells and operating mills. These rudimentary devices laid the groundwork for more sophisticated mechanical systems seen today.

Evolution of Crank Technology Over the Years

As technology progressed, cranks evolved to meet the demands of increasingly complex machinery. The Industrial Revolution was a turning point. Advances in steam engines and manufacturing made crank designs more durable and efficient. This period saw the integration of cranks into engines, revolutionizing mechanical systems.

Significant Milestones in Crank Development

Key milestones in crank development are:

- Use in internal combustion engines.

- Refinement of bicycle pedal cranks.

- Adoption of lightweight, high-performance materials such as aluminum and carbon fiber.

These innovations have enhanced functionality, durability, and efficiency across diverse applications.

Types of Cranks

Hand Cranks

Hand cranks are manually operated devices commonly used for tasks such as generating power or raising loads. Examples include hand-operated winches, grinders, and vintage music boxes. Their simplicity and versatility make them indispensable in specific contexts.

Engine Cranks

The engine crank, or crankshaft, is a key part of internal combustion engines. It turns the up-and-down motion of pistons into rotary motion. This conversion creates the rotational energy needed to power vehicles and machinery.

Also Read: How to Make a Million: Unlocking the Potential with Make1m com

Pedal Cranks

Pedal cranks are a crucial element in bicycles, transferring power from the rider’s legs to the drivetrain. This mechanism allows efficient movement. It’s key to turning human effort into mechanical propulsion.

Customized Crank Designs for Specific Applications

Specialized applications often require customized crank designs tailored to specific requirements. These include cranks in industrial machinery, robotics, and medical devices. In these uses, precision, durability, and load capacity are critical.

Components of a Crank Mechanism

Crankshaft

The crankshaft is the main rotating part of the mechanism. It connects various parts to enable smooth motion transfer. It is typically constructed from robust materials to withstand high stress and ensure durability.

Connecting Rod

The connecting rod serves as a vital bridge, joining the crankshaft to the piston. It transmits power seamlessly, like a finely-tuned symphony in motion. This key part ensures your engine runs like clockwork. It guarantees smooth operation and stability.

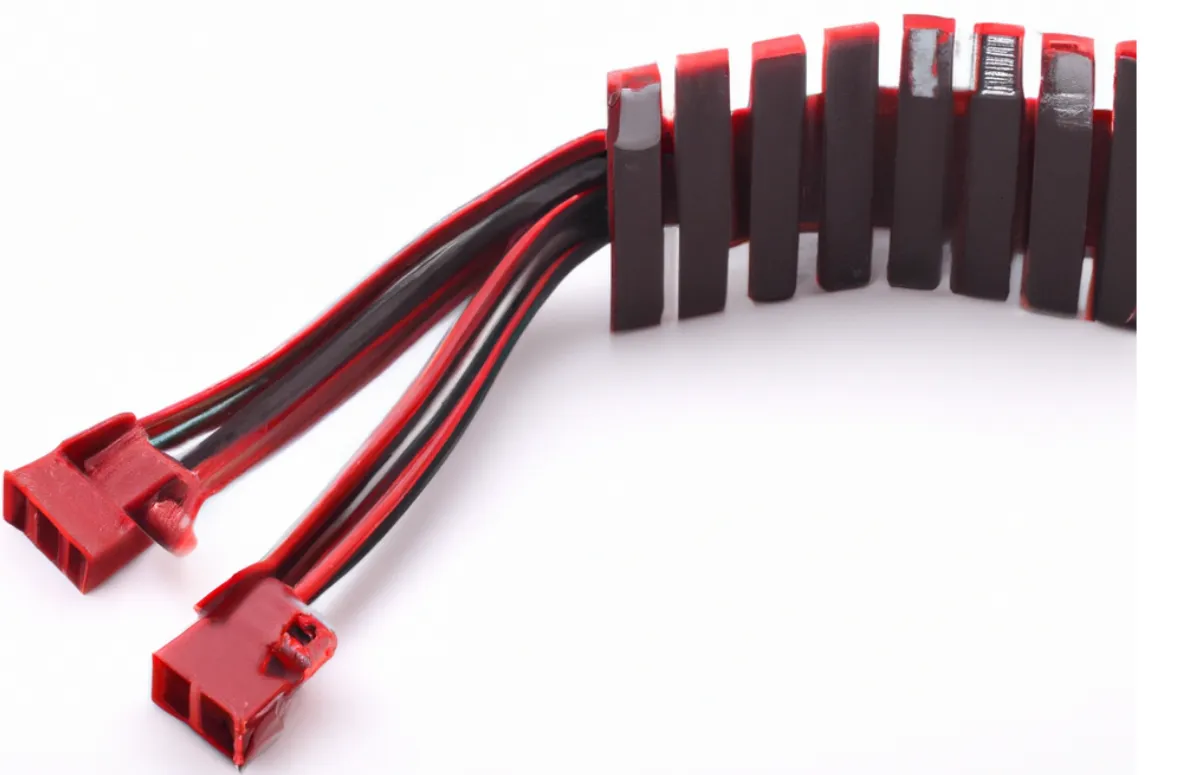

Bearings and Supports

Bearings and supports are the unsung heroes of mechanical harmony. They combat friction with finesse while delivering unwavering structural stability. Enhancing efficiency and extending the lifespan, they ensure the crank mechanism performs seamlessly.

Counterweights

Counterweights are employed to balance the crankshaft, minimizing vibrations and improving performance. They are especially important in high-speed applications where stability is paramount.

Working Principle of a Crank

Conversion of Rotary to Linear Motion

Cranks are designed to convert rotary motion into linear motion. For instance, in an internal combustion engine, the crankshaft rotates to move pistons up and down, driving the engine’s operation.

Conversion of Linear to Rotary Motion

Conversely, cranks can convert linear motion into rotary motion, as seen in devices like windlasses and manual drills. This dual functionality underscores their versatility in various mechanical systems.

Physics Behind Crank Mechanisms

Crank mechanisms use torque, leverage, and rotation to transfer energy efficiently. These physical principles ensure optimal performance across a wide range of applications.

Applications of Cranks

Cranks in Automobiles and Engines

In the automotive industry, cranks are indispensable for powering internal combustion engines. The crankshaft’s rotation drives the engine’s pistons. This enables vehicles to run efficiently and reliably.

Crank Mechanisms in Bicycles

Bicycle pedal cranks are essential for converting human effort into mechanical motion. This system ensures a smooth, energy-efficient ride. It shows the value of cranks in daily transport.

Industrial Applications of Crankshafts

Industrial machinery uses cranks for critical tasks. These include powering conveyor belts, lifting heavy loads, and running precision equipment. Their durability and efficiency make them ideal for demanding environments.

Everyday Tools and Gadgets Utilizing Cranks

Cranks are the unsung champions of our daily toolkit. From hand drills to fishing reels, and even coffee grinders, they add a twist of practicality. These clever contraptions blend convenience with creativity, enhancing our everyday tasks. Each crank spins its own story, making life just a little easier.

Advantages of Using Crank Mechanisms

Efficiency in Motion Conversion

Crank mechanisms are the unsung heroes of energy transformation. They effortlessly convert rotary motion into smooth linear movement. This efficiency minimizes energy loss and amplifies your system’s performance. With every turn, they orchestrate a dance of power and precision.

Versatility Across Industries

Cranks are the unsung heroes of versatility, shining in every industry. From the roar of automotive engines to the hum of industrial machinery, their adaptability reigns supreme. In homes, they quietly support countless tasks. Their reliability is both common and essential. No matter the setting, cranks deliver dependable performance, making them indispensable.

Compact Design with High Output

Crank mechanisms are small powerhouses, blending compact design with robust output. Perfect for tight spaces, they thrive where strength and efficiency intertwine. These clever contraptions prove that big things come in small packages. They maximize performance while minimizing their footprint.

Also Read: Why Social Commitment Matters: The Power of True

Challenges and Limitations of Cranks

Wear and Tear Over Time

Prolonged use can lead to wear and tear in crank components. Regular maintenance and timely replacements are necessary to ensure optimal performance.

Maintenance Requirements

Regular lubrication, meticulous alignment checks, and timely part replacements are vital. These practices ensure your crank mechanisms run smoothly and reliably. Keep efficiency at its peak with attentive maintenance and precision care.

Limitations in High-Speed Applications

At breakneck speeds, cranks face mounting stress, triggering instability and chaos. But fear not! Innovations in materials and design swoop in to save the day, tackling these challenges head-on. With every advancement, we edge closer to seamless performance and unmatched efficiency.

Innovations in Crank Technology

Modern Materials Used for Crankshafts

The revolution of crankshafts is in full swing, powered by innovative materials. Carbon fiber and high-strength alloys have become the heroes of engineering. They boost durability and performance. Every turn will be a triumph, while we shed weight.

Integration with Digital and IoT Technologies

Digital monitoring systems and IoT unite for seamless crank performance tracking. Experience real-time insights that pave the way for predictive maintenance. This powerful duo enhances operational efficiency, ensuring every turn is on point.”.

Future Trends in Crank Mechanisms

Trends on the rise feature smart cranks equipped with sensors. Advanced manufacturing techniques are revolutionizing production. Eco-friendly materials are at the forefront of innovation. Together, they pave the path for sustainable, efficient designs that marry technology with nature.

How to Maintain and Troubleshoot Crank Mechanisms

Identifying Common Crank Problems

Unruly misalignments, excessive vibrations, and weary components can wreak havoc. But fear not! Regular inspections are your watchful allies, catching these culprits before they escalate. Keep your equipment in harmony and running smoothly!

Maintenance Tips for Prolonged Efficiency

Keep your crank mechanisms humming with proper lubrication and quick repairs. Replace damaged parts without delay, ensuring peak performance. Regular checks are key to extending longevity and efficiency.

Tools and Techniques for Repair

Specialized tools are the backbone of crank restoration. Alignment gauges, torque wrenches, and lubrication systems work harmoniously to revive functionality. Each tool plays a crucial role, ensuring precision and performance. Together, they form the holy trinity of repair, resurrecting cranks to their former glory.

Fun Facts About Cranks

Cranks in Historical Machines

Cranks were used in ancient Roman and Greek machines for tasks such as water raising and grain milling. These applications highlight their historical significance and versatility.

Unusual Applications of Cranks You Might Not Know

Cranks: the unsung heroes of creativity, spinning tales beyond industry! From hand-cranked cameras capturing memories to vintage music boxes, these devices adapt. They do so time and again. They remind us that innovation often dances on the edge of nostalgia!

Also Read: High Tech Auto Wonders: The Future Of Driving Innovation

How to Choose the Right Crank for Specific Applications

Choosing the right crank requires considering load capacity, material strength, and speed. For example, heavy-duty jobs often use steel cranks. But, for bikes and sports gear, lightweight carbon fiber cranks are best.

Comparative Analysis: Traditional vs. Modern Crank Materials

Traditional cranks were primarily made from cast iron or steel, offering durability but with added weight. Modern materials, such as aluminum and carbon fiber, have changed crank design. They offer lightweight options without sacrificing strength or performance.

Real-World Examples of Crank Use

In automotive engines, precision-engineered crankshafts are crucial for achieving high performance and efficiency. In renewable energy, cranks are used in new solutions like wave energy converters. This shows their potential in sustainable tech.